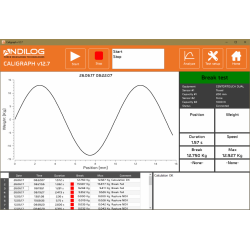

Caligraph - Data acquisition and analyzing software for Centor series

- User-friendly intuitive user interface for fast start

- Display of the curve in real time for force and torque gauges

- Automatic pre-defined calculations: maximum, break, average

- Creation of personalizable test reports

- Permanent updates and support