A Force Gauge is measuring instrument used across all industries to measure the force during a push or pull test. Applications exist in research and development, laboratory, quality, production and field environment. There are two kind of force gauges today: mechanical and digital force gauges.

A digital force gauge is basically a handheld instrument that contains a load cell, electronic part, software and a display. A load cell is an electronic device that is used to convert a force into an electrical signal. Through a mechanical arrangement, the force being sensed deforms a strain gauge. The strain gauge converts the deformation (strain) to electrical signals. The software and electronics of the force gauge converts the voltage of the load cell into a force value that is displayed on the instrument.

Test units of force measurements are most commonly newtons or pounds. The peak force is the most common result in force testing applications. It is used to determine if a part is good or not. Some examples of force measurement: door latch, quality of spring, wire testing, strength ... but most complicated tests can be performed like peeling, friction, texture.

Digital force gauges use strain gauge technology to measure forces. The principle is as follows :

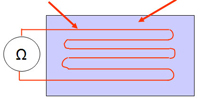

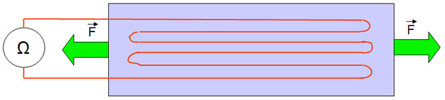

The strain gauge A strain gauge is composed of a resistive track and a deformable support. | |||

| Resistive track | Deformable body | ||

| |||

| Body deformation | |||

| |||

| |||

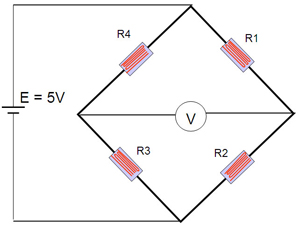

The Wheatstone Bridge To measure the change in force, the change in resistance of the strain gauges is measured. To carry out this measurement, we use an electrical arrangement called a Wheatstone bridge as shown opposite. This circuit is in fact composed of 4 strain gauges placed in parallel in order to have a better linearity of the measurement.Powered under constant voltage, the variation of the strain gauges varies the voltage measured by the Voltmeter on the diagram above. The value measured by V is proportional to the variation of the strain gauges according to the following formula : V = (E x (R1 / (R1 + R4)) - E x (R2 / (R2 + R3)) | |||

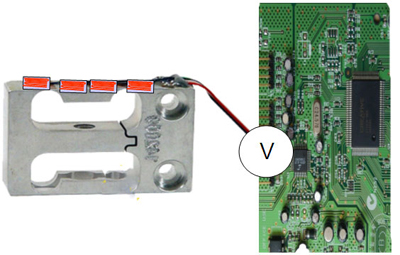

From the strain gauge to the force gauges | |||

| Analogic | Digital | ||

| Software Processing Filters Calculations  | ||

| To be integrated into a force gauge, the strain gauges are carefully bonded to a deformable aluminium or steel body depending on the measuring capacity. This body has a special geometry that ensures a large and repeatable deformation. The strain gages must fit perfectly to the support to ensure a good measurement. | The measurement of voltage variation is carried out by an electronic acquisition board which converts the measured analog signal into a digital signal. | This electronic board also includes a software which allows to condition the information: filtering of the values, calculations (maximum for example), RS232 output... | |

| |||

| Finally, the software transmits the information to the display, which allows to display the measurements, the results, draw a curve etc.. The whole of its elements constitute a force gauge which is moreover equipped with a battery and a protective shell to make it autonomous and portable. | |||