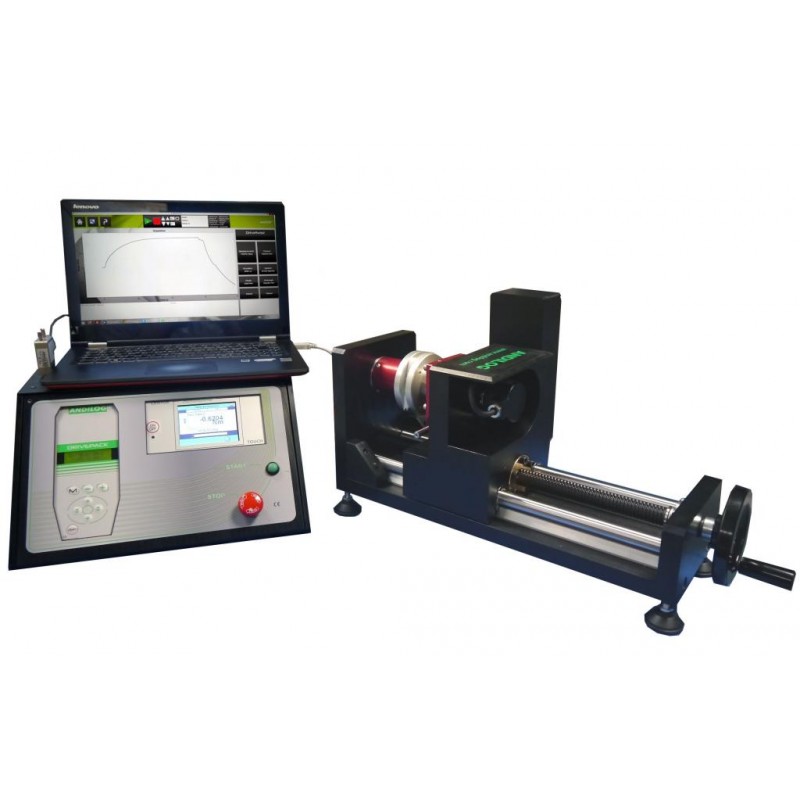

Califort - Control and data acquisition software for test machines

- User-friendly interface

- Intuitive programming of tests

- Edition and creation of customized test reports

- Permanent updates and support

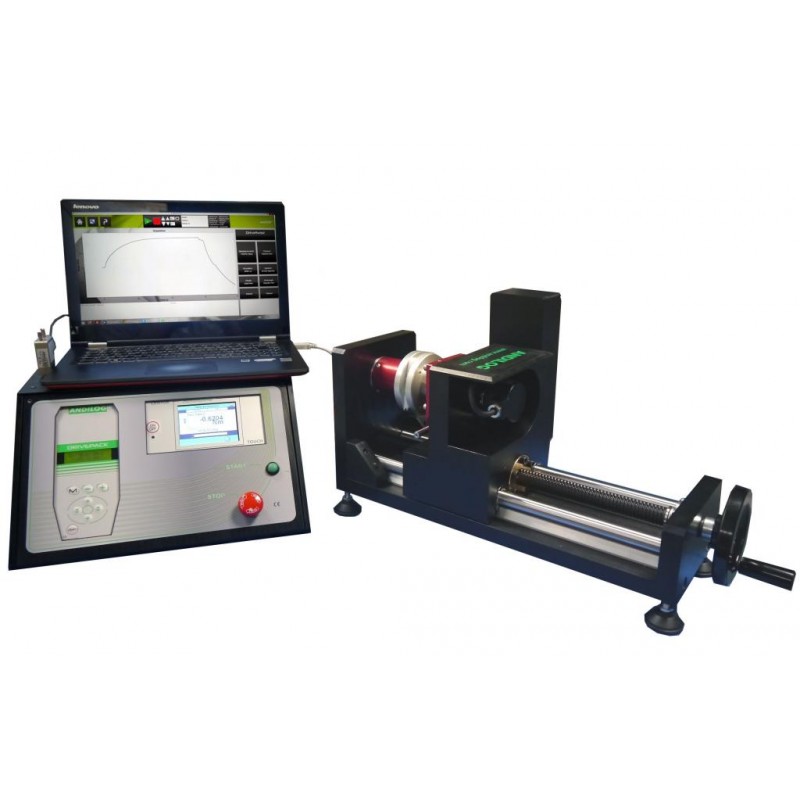

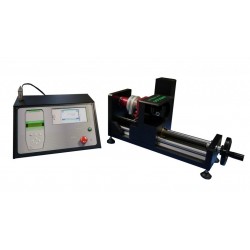

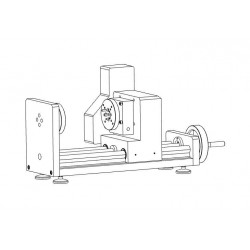

The DriveTwist model is an automated torque test bench for all static torque measurement. It offers high accuracy, repeatable testing and large versatility for torsion applications. It's specially designed to determine the torsion properties of components subjected to twist loading in service. Thanks to its motorized command, set the speed of your test protocol and perform your torsion test without the influence of the operator.

The DriveTwist suits a large broad of applications: spring torsion test, material testing, component testing, rotary actuators for rotation, torsional stiffness.

Available capacities : 1, 3, 6, 12 and 24 Nm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

You might also like

Califort - Control and data acquisition software for test machines